Custom Corrugated Sheets and Pats

Custom corrugated sheets and pads offer tailored protection and support for your packaging needs.

Introduction of Custom Corrugated Sheets and Pats

Designed to provide exact answers for different packaging requirements, custom corrugated sheets and pads Protecting goods during transit and handling calls for these customized products, which also guarantee great condition upon arrival.

Perfect for use as liners or dividers within boxes, custom corrugated sheets may be created to exact sizes and strengths. By tightly keeping goods in place, they help to stop movement and damage.

Corrugated pads give extra padding and support, which is vital for preserving product stability—especially for difficult or heavy items. Customizing the style and size of these sheets and pads will help you to meet special packaging needs and improve the general effectiveness of your packing operation.

Custom corrugated sheets and pads provide a consistent and efficient answer whether you are delivering bigger goods or delicate electronics.

Why Choose Custom Corrugated Sheets and Pats

Custom corrugated sheets and pads offer tailored solutions for your packaging needs. By choosing custom options, you get sheets and pads that fit your products perfectly, ensuring they’re protected during transit.

Custom corrugated sheets can act as dividers or liners to secure items and prevent shifting, while custom pads provide additional cushioning and support. This customization helps address specific challenges and enhances the stability of your packages.

It improves the efficiency of your packaging process, minimizes waste, and ensures your products arrive safely. Custom corrugated sheets and pads are a practical choice for both delicate and heavy items.

How to Choose Custom Corrugated Sheets and Pats

Select custom corrugated sheets and pads based on size, strength, and specific product protection needs.

Find Your Custom Corrugated Sheets and Pats by Suitable Corrugated Flute

To find the right custom corrugated sheets and pads, you need to choose the suitable corrugated flute. T

he flute type affects the strength and cushioning of the material. For heavier items or high-impact protection, thicker flutes like C or B flutes are better as they offer more support and cushioning.

For lighter products or less demanding needs, A flute might be sufficient. Selecting the right flute ensures your sheets and pads provide the protection and stability your items require.

Consider your packaging needs and the weight of your products to pick the best flute type for your custom corrugated solutions.

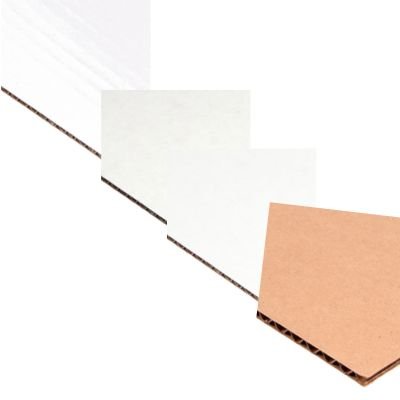

Find Your Custom Corrugated Sheets and Pats by Material

Choosing the right material for custom corrugated sheets and pads is key to ensuring your products are well-protected. Single-wall corrugated board works well for lighter items, while double-wall offers extra durability for heavier or more fragile products.

For maximum strength, especially in demanding situations, triple-wall corrugated board is the best choice. Additionally, if you need protection against moisture or other specific conditions, consider materials with those properties.

By selecting the right material, you ensure that your custom sheets and pads provide the necessary support and protection, tailored to your packaging needs. Evaluate your requirements to choose the most suitable material.

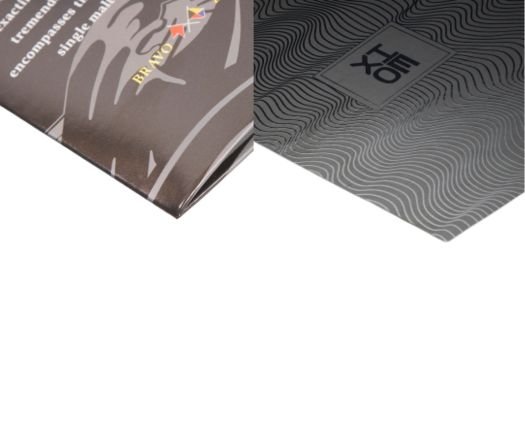

Find Your Custom Corrugated Sheets and Pats by Printing Method

When choosing custom corrugated sheets and pads, the printing method matters. Flexographic printing is a good option for large orders and offers reliable color quality, while digital printing works well for smaller runs and detailed graphics.

Decide if you need single-color or multi-color prints and if your design includes logos or product information. The right printing method will ensure your sheets and pads not only protect your products but also display your branding or details effectively.

Pick the method that best suits your design needs and budget for a practical and visually appealing packaging solution.

Aqueous coating

UV Coating

Soft Touch Coating

Lamination

Embossing

Hot Foil Stamping

Still have no idea?

Leave your needs of details and your contacts, our corrugated specialist will repy within 1 workday

About Us

We specialize in creating custom corrugated boxes designed to meet your unique needs with precision and quality.

At our company, we pride ourselves on delivering high-quality, custom corrugated boxes designed to meet your specific packaging needs. With years of experience and a dedication to excellence, we provide solutions that enhance product protection, streamline logistics, and elevate brand presentation. Our expertise extends to custom corrugated sheets and pads, ensuring that every aspect of your packaging is optimized. We work closely with you to make sure each box and accessory not only performs effectively but also reflects your brand perfectly. Trust us to be your partner in achieving packaging success.

- We design custom corrugated boxes that perfectly match your product’s specifications and branding needs.

- Our boxes are made from premium materials, ensuring durability and reliable protection for your products.

- Each box is crafted to enhance your brand’s presentation, making a strong impression on your customers.

- We work closely with you, offering personalized service to achieve the best packaging results for your business.

Corrugated Types

Our Advantages

Why Choose Us For Your Custom Corrugated Sheets and Pats Solution

We provide custom corrugated sheets and pads specifically designed to meet your unique packaging needs, ensuring a perfect fit for your products.

Our products are made from top-grade materials, offering durability and strength to protect your items during transit and storage.

With years of experience in the industry, our team uses precise techniques to deliver custom solutions that meet your exact specifications.

We offer various printing options to help you showcase your brand effectively on custom corrugated sheets and pads, enhancing your product’s market presence.

Our custom solutions are designed to streamline your packaging process, improving efficiency and reducing overall costs.

We are dedicated to delivering exceptional quality and service, ensuring your custom corrugated sheets and pads meet the highest standards.

How Work With Us

4 Steps Get Your Customize Packaging

Step 3

Step 2

Step 1

Customize Your Corrugated Box

Create a custom corrugated box that perfectly matches your product’s size, style, and protection requirements, all with our expert craftsmanship.

The Inspiration of Custom Corrugated Sheets and Pats

FAQ of the Custom Corrugated Sheets and Pats

Custom corrugated sheets and pads offer customized protection and support, ensuring optimal packaging for your products.

What are custom corrugated sheets and pads?

Custom corrugated sheets and pads are designed packaging solutions made from corrugated cardboard. They provide specific protection and support tailored to various products. These sheets and pads can be customized in size, strength, and design to meet unique packaging needs. They help safeguard items during shipping and storage, reducing damage risk. Options include different thicknesses, sizes, and printing to align with particular requirements and branding goals.

How are custom corrugated sheets and pads made?

Custom corrugated sheets and pads are produced by combining layers of corrugated cardboard. The process involves layering a linerboard with a fluted medium to create a durable, cushioned material. The cardboard is then cut and shaped to specific dimensions, with additional customization options such as printing designs or logos. Choices include single-wall, double-wall, or triple-wall constructions, offering varying levels of strength and protection based on the application.

What are the benefits of using custom corrugated sheets and pads?

Custom corrugated sheets and pads enhance protection by minimizing the risk of damage during transport and storage. They ensure a precise fit for items, improving stability and reducing movement within packages. Customization options, including printed designs and logos, enhance branding and presentation. Tailored solutions streamline the packaging process by addressing specific needs, leading to improved overall efficiency.

What types of materials are used for custom corrugated sheets and pads?

Materials for custom corrugated sheets and pads include single-wall, double-wall, and triple-wall corrugated boards. Single-wall is suitable for lighter items, while double-wall offers additional strength for heavier products. Triple-wall corrugated board provides the highest durability and protection for demanding applications. The choice of material depends on specific needs, including product weight, fragility, and the required level of cushioning.

How do you choose the right custom corrugated sheets and pads?

Selecting the appropriate custom corrugated sheets and pads involves considering the size and weight of the products, as well as the level of protection needed. It is important to determine whether single-wall, double-wall, or triple-wall construction best suits the requirements. Also, evaluate any specific design or branding needs and ensure the dimensions match packaging specifications. Consulting with packaging experts can help in making the most suitable choice.

What sizes are available for custom corrugated sheets and pads?

Custom corrugated sheets and pads are available in a wide range of sizes to meet various packaging needs. They are cut and shaped to fit products precisely, ensuring an optimal fit. Whether large sheets for bulkier items or smaller pads for delicate products are needed, customization allows for exact dimensions and shapes. This flexibility ensures functionality and a tailored approach for different applications.

What factors influence the cost of custom corrugated sheets and pads?

The cost of custom corrugated sheets and pads is influenced by factors such as material type, size, and thickness. Additional considerations include the complexity of customization, such as printing or unique design features. Order volume also affects pricing, with larger quantities often reducing the per-unit cost. Customization options like special coatings or finishes can impact the final price. Consulting with a supplier can help understand how these factors affect overall costs.

Are custom corrugated sheets and pads eco-friendly?

Custom corrugated sheets and pads are often made from recyclable materials, offering an eco-friendly packaging solution. The corrugated cardboard used can be recycled and repurposed, helping to reduce waste and minimize environmental impact. Many manufacturers also adhere to sustainable production practices. Choosing these solutions supports more sustainable packaging and contributes to a reduced carbon footprint.

How do custom corrugated sheets and pads improve packaging efficiency?

Custom corrugated sheets and pads enhance packaging efficiency by providing a precise fit for products, reducing excess material and waste. They stabilize items, preventing movement and damage during transport. Custom solutions streamline the packing process, making it quicker and more efficient. Improved organization and handling contribute to a more streamlined operation, saving time and resources.

Can samples of custom corrugated sheets and pads be requested before placing a large order?

Samples of custom corrugated sheets and pads can be requested before committing to a large order. This allows for evaluation of quality, fit, and design to ensure they meet specific requirements. Sampling confirms that the materials and customization align with expectations, ensuring that the final product will perform as needed and meet packaging demands.